I’m building a RepRap Prusa Mendel 3D printer for producing enclosures for these projects. I got the printed parts from Hawkins Electronics, and am waiting for the final batch of vitamins to come in before I can complete assembly.

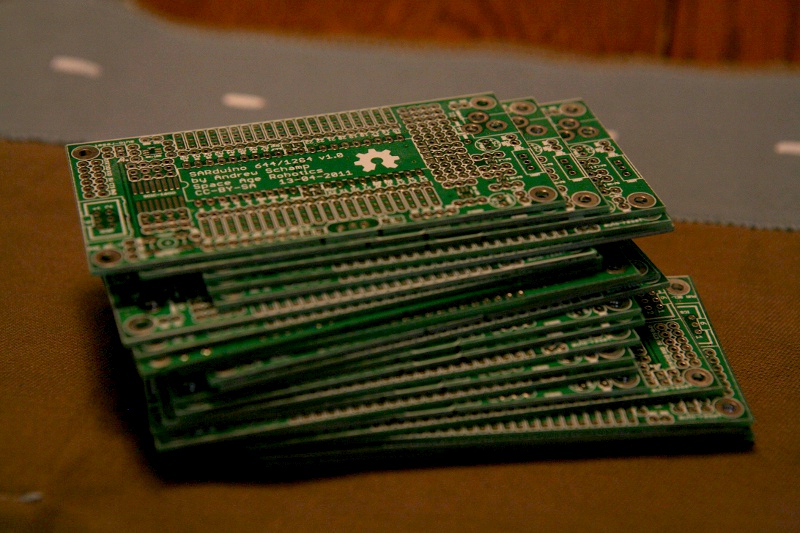

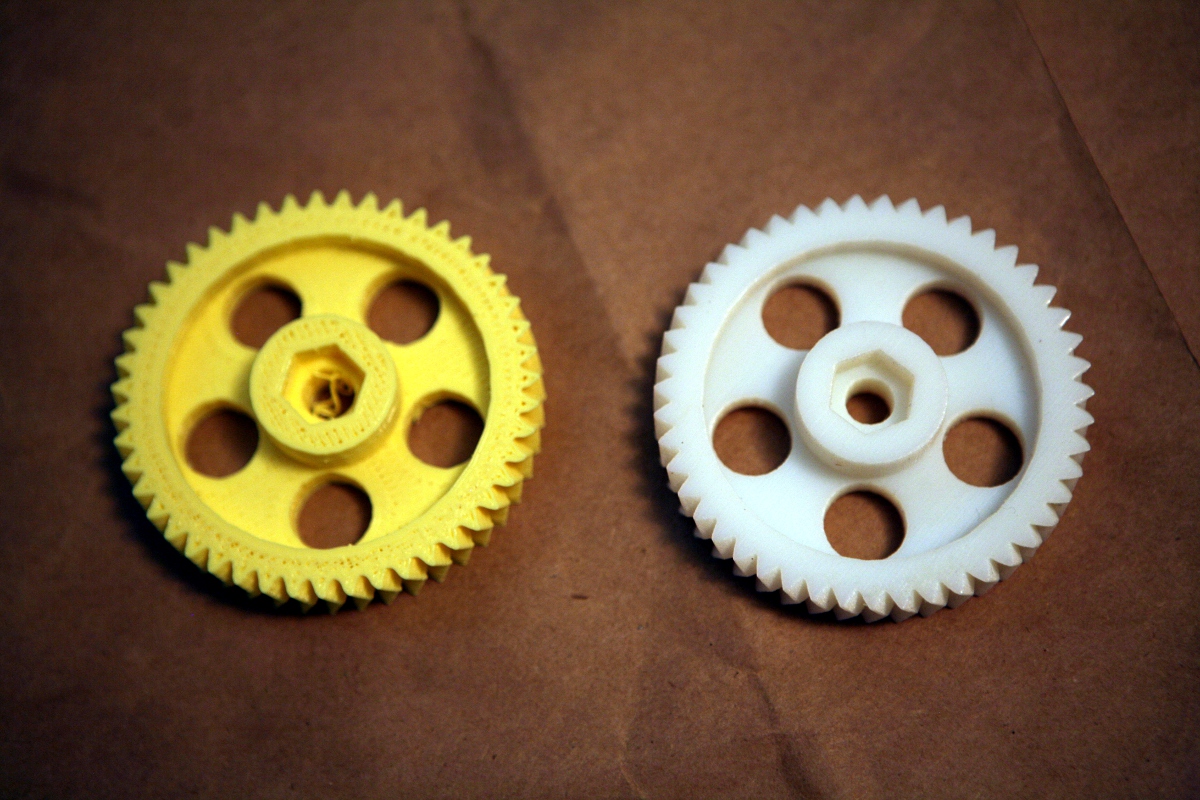

A while back, I posted an Instructable about panelizing PCBs at Seeed for a contest Instructables was having. I didn’t win, but my Instructable was featured, and so as a prize I received a free 3D printed part of my choice, evidently made from Autodesk 123D. Since the quality of the 3D printed gears seem to make the most difference in RepRap performance, I ordered an instance of the large extruder gear from the “Greg’s Wade reloaded” extruder I was using. It arrived the other day, and I promised the guys at Hawkins I’d post a comparison. Let me say up front that while the Hawkins gear fares rather poorly in the comparison, it was produced on settings that were a compromise for between speed, material use, and quality, and was not intended to compete.

Here we have the Hawkins gear on the left, and the Autodesk one on the right. They are both made of PLA (as far as I can tell). The main difference is in the infill – the Autodesk gear seems to have 100% infill, while the Hawkins gear has something less. The Autodesk gear is therefore more solid, and its teeth are well formed.

Here we have the Hawkins gear on the left, and the Autodesk one on the right. They are both made of PLA (as far as I can tell). The main difference is in the infill – the Autodesk gear seems to have 100% infill, while the Hawkins gear has something less. The Autodesk gear is therefore more solid, and its teeth are well formed.

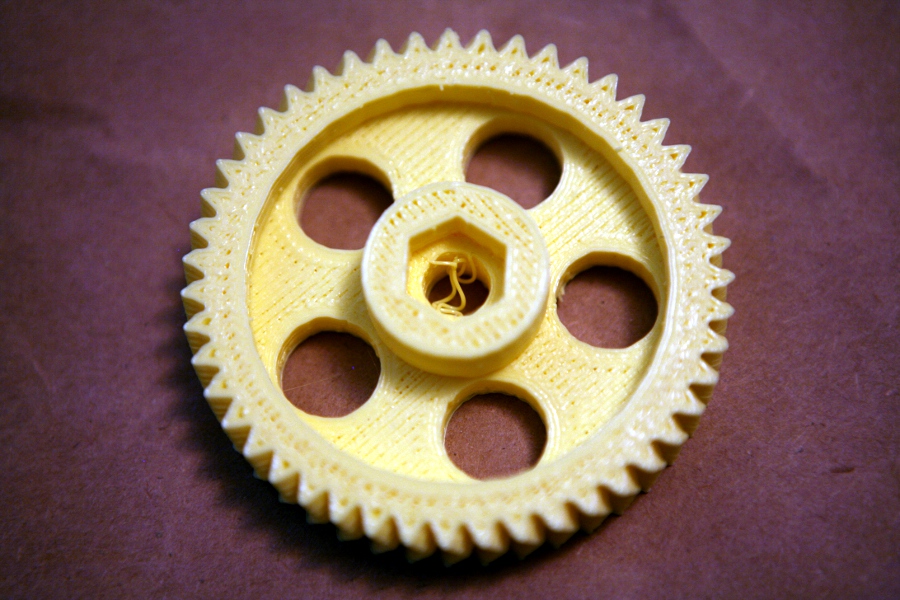

Here you can see a closeup of the Hawkins gear. Note the evident partial infill, which extends even to the teeth of the gear. It is not visible from this side, but there is a small area with two or three teeth that are a bit deformed. I attribute this mainly to the reduced infill. It is not enough to affect its operation as far as I can tell, but it may cause an increased chance of binding as the parts deteriorate over time. Note also the snazzy yellow color, which I prefer.

Here you can see a closeup of the Hawkins gear. Note the evident partial infill, which extends even to the teeth of the gear. It is not visible from this side, but there is a small area with two or three teeth that are a bit deformed. I attribute this mainly to the reduced infill. It is not enough to affect its operation as far as I can tell, but it may cause an increased chance of binding as the parts deteriorate over time. Note also the snazzy yellow color, which I prefer.

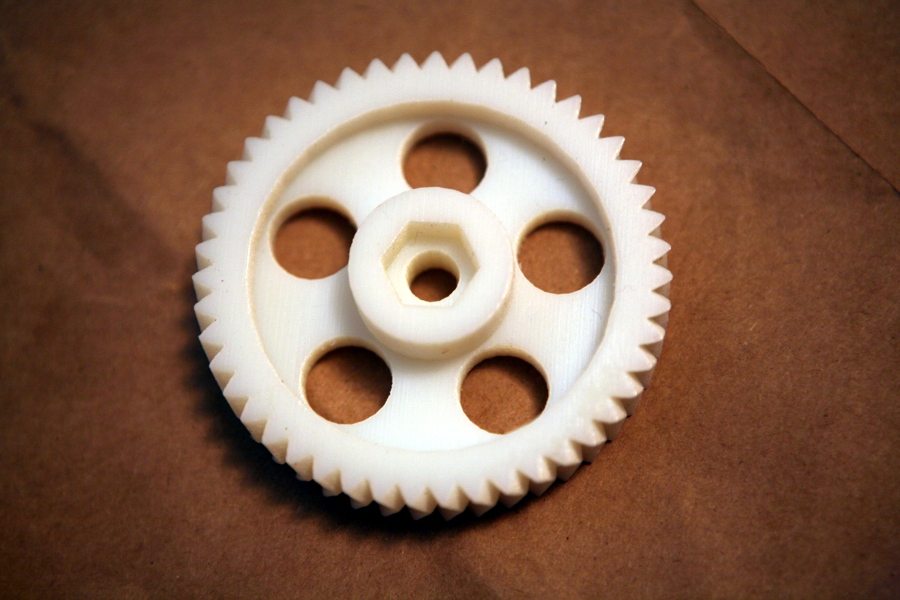

Here you can see in more detail the Autodesk gear. In addition to the complete infill, it appears to be of slightly higher resolution. The gear teeth are noticeably smoother and more uniform than the Hawkins gear. It also has a bit more heft, due no doubt again to the infill.

Here you can see in more detail the Autodesk gear. In addition to the complete infill, it appears to be of slightly higher resolution. The gear teeth are noticeably smoother and more uniform than the Hawkins gear. It also has a bit more heft, due no doubt again to the infill.

I hope to post more on the RepRap as the machine comes together. What could be more fitting for a robotics company than a robot that makes other robots?